Aseptic Test Isolator

Product principle As a sealed system, thesterility inspection isolator is designed to realize safe air exchange throughf

Send your inquiryDESCRIPTION

Basic Info

| Type | Aseptic Subpackaging and Inspection Machine |

| Finished Dosage Form | Liquid and Powder |

| Precision | High Precision |

| Certification | CE, GMP, ISO, UL |

| Voltage | 220V |

| Computerized | Computerized |

| Customized | Customized |

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | Provide Instructions and Videos, Online Video Guid |

| Core Components | PLC, Pump, Bearing, Gearbox, Motor |

| Clean Grade | Class a |

| Power | AC220V±22V 50Hz±1Hz |

| Sterilization Concentration Range | 0-1000ppm |

| Falling Air Velocity | 0.36--0.54m/S Adjustable |

| After Warranty Service | Field Installation, Commissioning and Training |

| Applicable Industrie | Hospital Ward, Airtight Cabin, Laboratory |

| Materials | PVC and SUS304 |

| Keyword | Aseptic Isolator |

| Certificate | CE, ISO, SGS |

| Laminar Flow | Vertical Unidirectional Flow/Turbulent Flow |

| Noise | <=68dB(a) |

| Sterilization System | Vhp |

| Equipment Size | Customized |

| Data of Equipment | Iq Pq Oq Dq |

| Transport Package | Standard Export Wooden Case |

| Specification | 1800*880*2250mm |

| Trademark | BIOGREEN |

| Origin | Wuxi, Jiangsu |

| HS Code | 8409919100 |

| Production Capacity | 1000PCS/Month |

Product Description

Product principle

As a sealed system, thesterility inspection isolator is designed to realize safe air exchange throughfan filter unit (high-efficiency particulate air(HEPA) filter) in a sealed environment, so as to continuouslycontrol the particles and microorganisms in the internal environment. When closed, the sterilityinspection isolator undergoesbiological decontamination treatment for its interior surface. The fasttransfer channel or airlock is utilized to carry out aseptic transfer of materials to ensure the protectionfromoperators todrugs.

Maximum power | ≤3000W |

Touch screen size | 12.1" industrial control screen |

Supply voltage | 220V±22V, 50±1Hz |

Airflow model in isolator cabin | Vertical unidirectional flow |

Pressure control range of cabin | -80 ~+80pa, to be adjusted |

Gas source | Filtered clean compressed air or nitrogen with a pressure of 0.4-0.6 MPa |

Leakage rate of the cabin | Conduct the testing of pressure maintaining at a positive pressure of 80Pa. The overall leakage rate of the isolator cabin isless than 0.5%vol/ hour |

Humidity resolution | 0.1% |

Temperature resolution | 0.1 ºC |

Wind speed | 0.36~0.54m/s |

Electronic signature | Available |

Online leak detection in cabin | Available |

Online glove leak detection | Available |

Data tracking | Available |

Dimensions | 313×125×217.5cm Can be customized |

Operating space | 179×105×74cm Can be customized |

Airlock space | 60×58×74cm Can be customized |

Product features

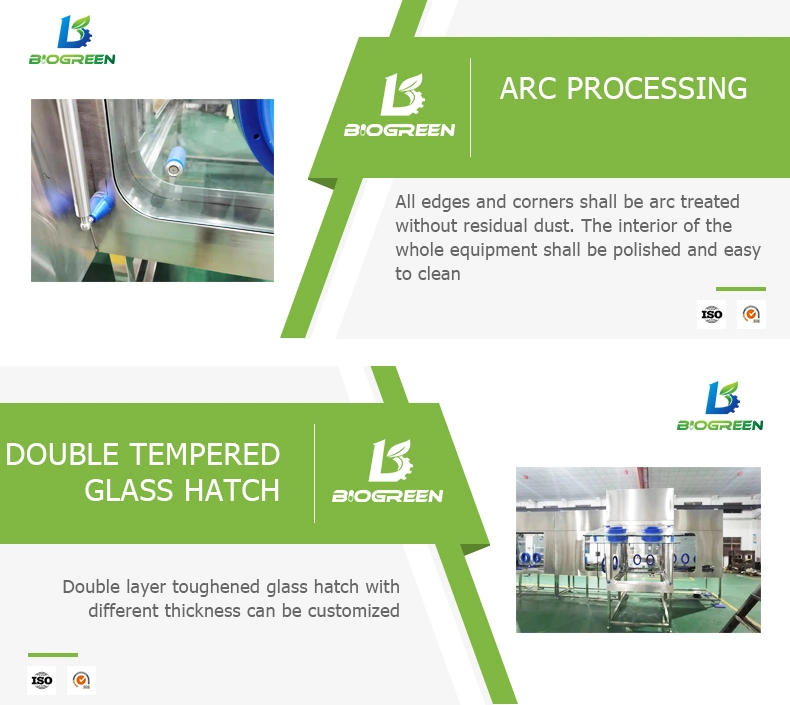

1. It adopts a rigid-wall structure, madeof stainless steel and tempered glass, with dynamic A-levelinternal environment;2. The gloves,in thickened and anti-breakage type, or in thin and comfortable type,are used in theoperation.3. It selects H14 high-efficiency particulate air filter and conducts scanning leak detection via PAO.4. Hydrogen peroxide can kill 106 spores on the air and exposed surface in the isolator.5. The safe entry and exit of materials can be realized by various means, such as airlock and transfercabin equipped with RTP system.6. A built-in power supply is installed in the isolator, and compressed air connector provided with valveand cleaning waterconnector are equipped for the purpose of water and air intake.7. This system is equipped with Siemens programmablelogic controller (PLC) for fully automatic controlof pressure and air supply,and supports the alarm function for pressure loss.8. The NetSCAD system of 10" touch screen/ 12.1" industrial tablet PC conforms to the verificationrequirements of GMP for computer system in 2010.

Related Products

-

![Voltplus Full Automatic Voltage Regulator 220V 2kVA Stac St 2000W 2kVA]()

Voltplus Full Automatic Voltage Regulator 220V 2kVA Stac St 2000W 2kVA

-

![Original IC Fpga 498 I/O 676fbga Xc6slx150-2fgg676c]()

Original IC Fpga 498 I/O 676fbga Xc6slx150-2fgg676c

-

![Full Bridge Based Peripheral Dri Low-Side Gate Driver IC Non-Inverting 8-Soic Integrated Circuits (ICs) Pmic Gate Drivers Fan3227tmx]()

Full Bridge Based Peripheral Dri Low-Side Gate Driver IC Non-Inverting 8-Soic Integrated Circuits (ICs) Pmic Gate Drivers Fan3227tmx

-

![Multilayer Ceramic Capacitors RF15N9R0B500CT 0402 9PF 50V NPO 0.1PF]()

Multilayer Ceramic Capacitors RF15N9R0B500CT 0402 9PF 50V NPO 0.1PF